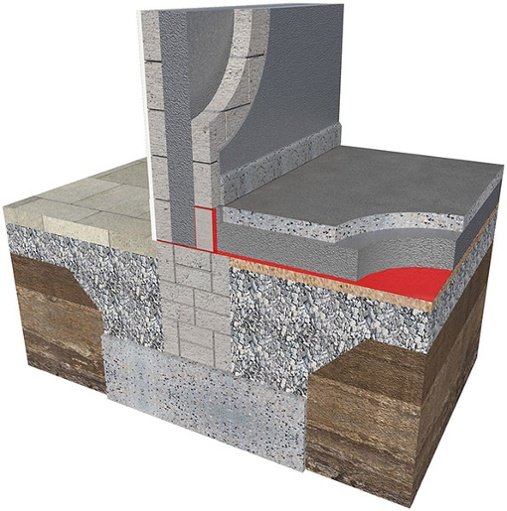

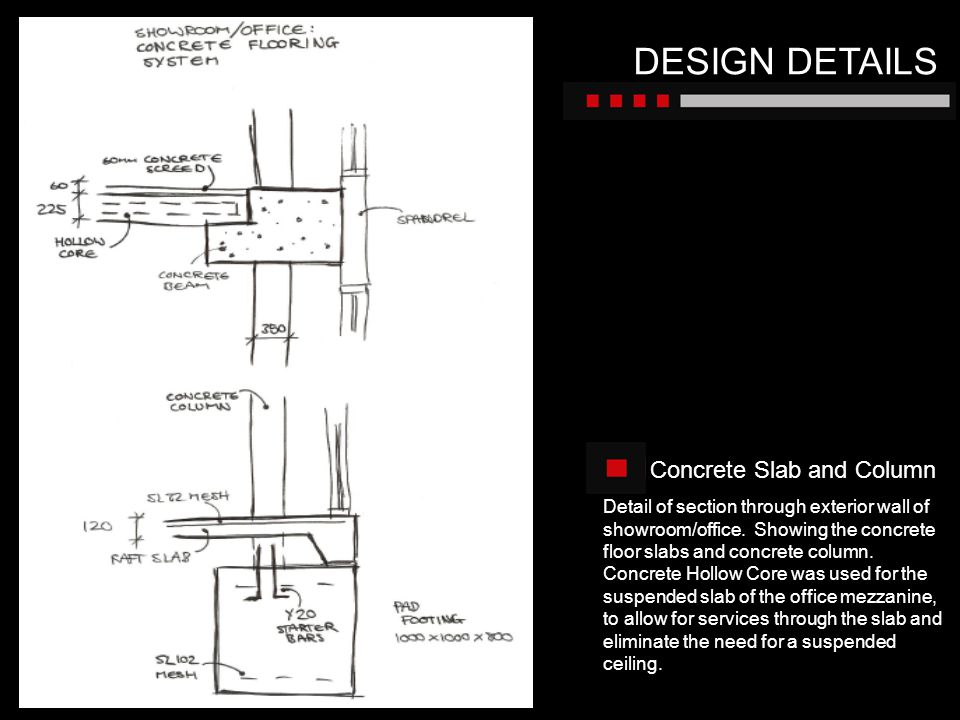

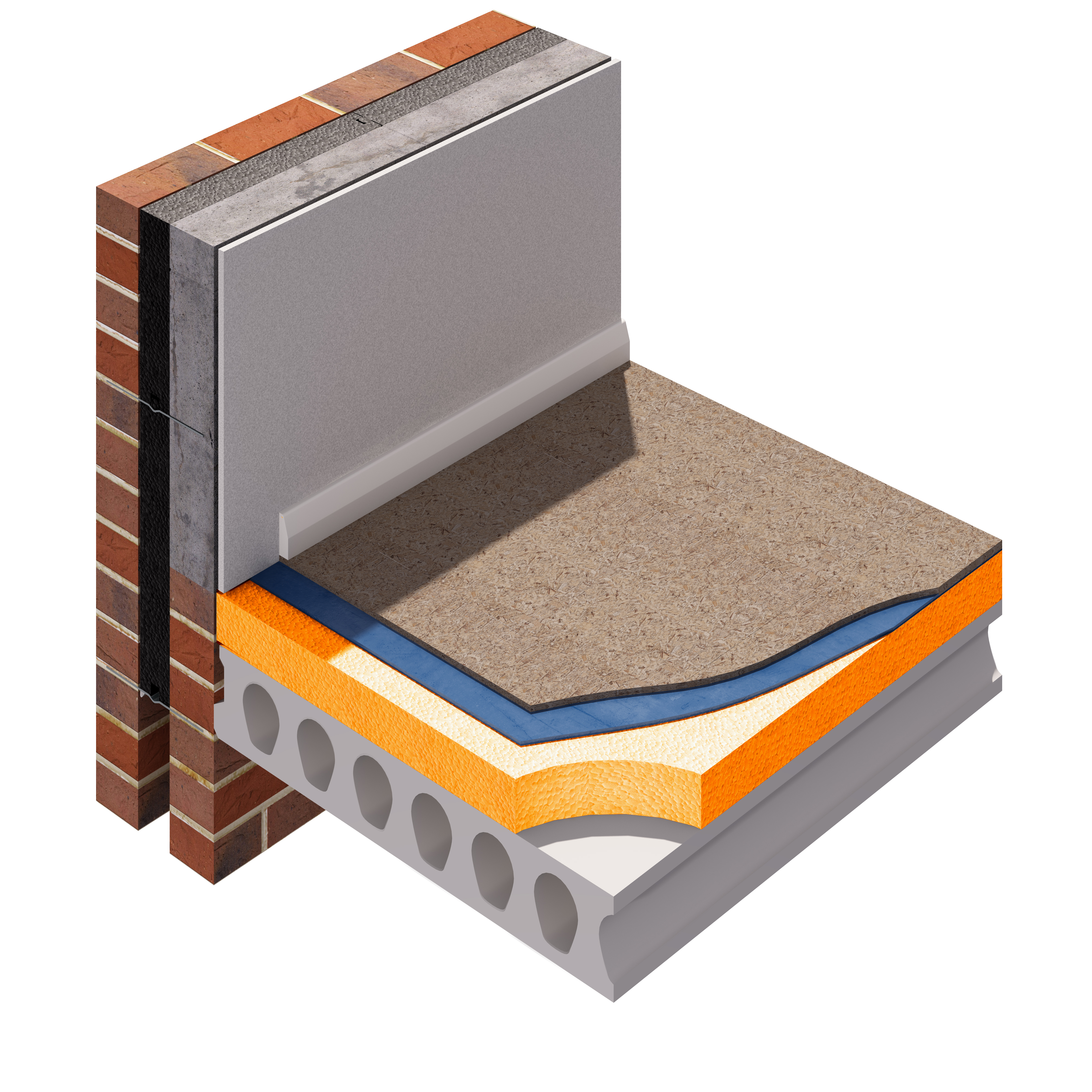

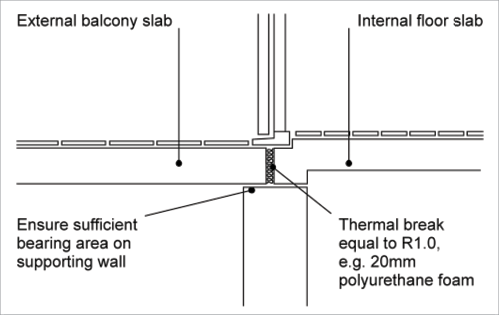

This chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 ContaminantsGround floors Ground bearing solid concrete floors Guidance Diagram 9 Typical section through a ground bearing solid concrete floor and foundation Guidance Table 5 Examples of insulation for ground bearing floor slabs Suspended reinforced insitu concrete ground floor slabPrecast Garage Floor suspended slabs are set in place and the keyway joints are then grouted AFTER Precast Garage Floor INSTALLATION Insert paper dam into Precast Garage Floor voids at least 6'' from each end

Suspended Floors All You Need To Know Thermohouse

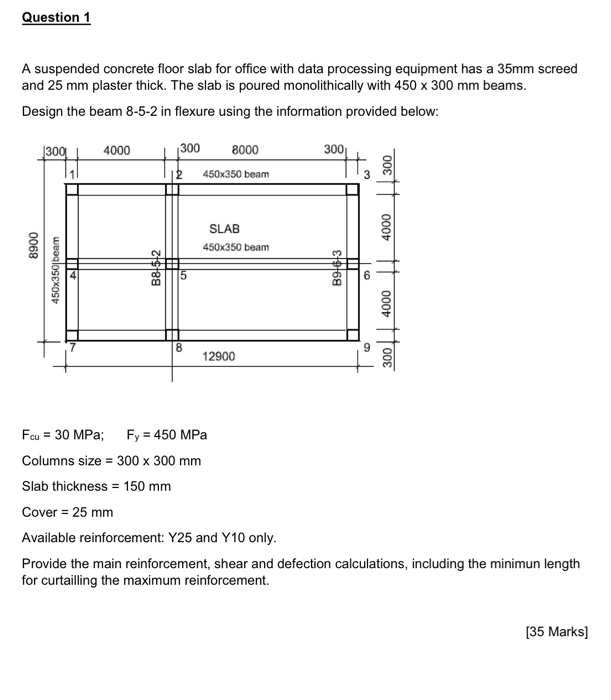

Suspended concrete floor slab design

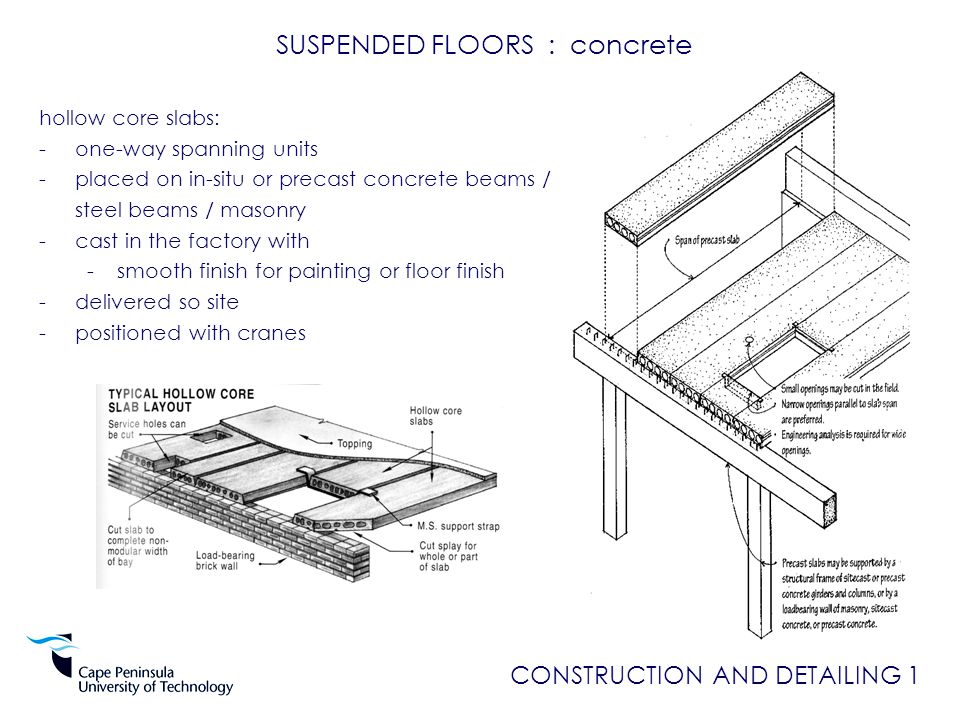

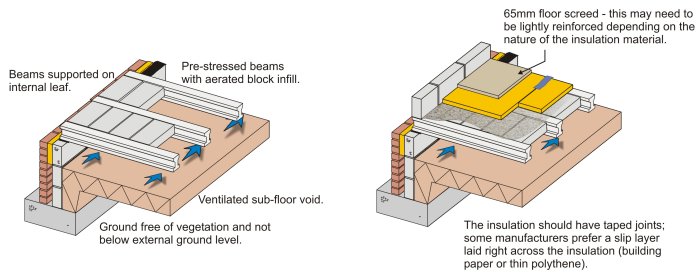

Suspended concrete floor slab design-Wide slab flooring is a high quality, economical suspended concrete floor construction using long prestressed concrete floor slabs (or planks) supported by either masonry walls or a supporting frame structure in steel or precast concrete In all instances floor slabs must be allowed to cure thoroughly before the floor is screeded and floor coverings laid It is also possible to construct suspended concrete floors by using a precast product, for example the popular beam and block system

Farm Structures Ch5 Elements Of Construction Floors Roofs

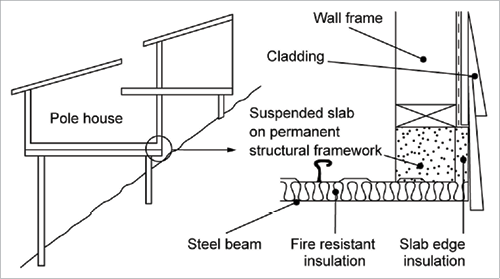

Openings in concrete floor slab systems can have a significant effect on oneway and twoway shear strength of the slab This effect is illustrated in this example for a concrete flat plate floor system shown in the figure below The floor opening is cut to accommodate typical mechanical, electrical, and piping (MEP) systems needed forMix, joint design and performance, and the slab thickness Floor Classifications Table 1 describes the nine classes of concrete floors according to ACI 302, Guide to Concrete Floor and Slab Construction This table details some of the special considerations and finishing techniques that are appropriate for each class of floorSuspended slabs are aboveground level slabs which are not directly in contact with the earth They are commonly used to create floors for the upper storeys of houses, but can also be sat on top of preconstructed walls to form a ground floor What are suspended slabs made of?

Firstfloor slab thickness The normal thickness used for reinforced concrete slabs in South Africa is 170 mm for small slabs, 255 mm for slabs larger than 5m x 5m and 340 mm thick for longspan slabs forming part of a beam and carrying heavier loads The thickness of a slab will depend on the use and span of the slabAs with particleboard flooring (see floors ), it provided a flat level surface on which to construct and erect wall frames Concrete slab floor construction was often used for internal garages or lower levels of split level houses, with suspended floors used for other parts of the houseThe Suspended Garage Slab Installation Process Coordinating with your architect, engineer, and contractor a composite design is created by a licensed professional engineer for your home After foundation is poured, field measurements are taken to ensure a good fit Steel is detailed, fabricated, and prime painted Steel is erected

Polished concrete floors are installed by grinding a concrete slab multiple times with progressively finer diamond grinding tools The first several steps are called 'cutting' and utilize aggressive grinding tools to remove imperfections and flatten and homogenize the floor's surface The number of cutting steps is a function of the desiredPrecast suspended slabs are constructed by pouring the slab I'm designing a suspended concrete slab over a concrete basement walls for a house garage 24'X24' plan dimension Ideally I would like to avoid beams, but I know locally (Missouri) it has been done with one or two steel W shape beams to support the slab

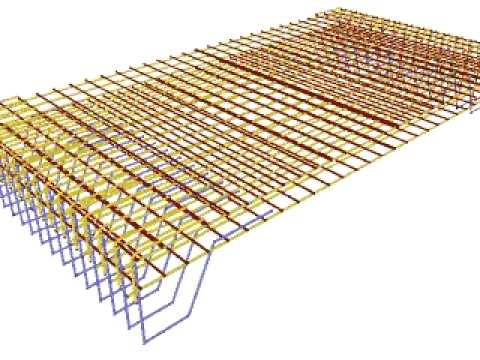

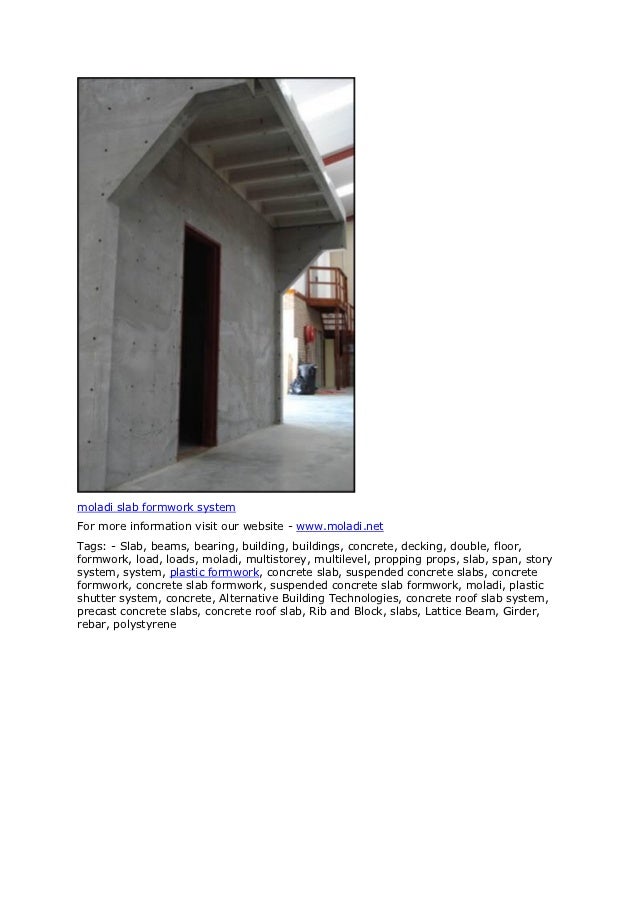

Suspended Concrete Floor Slab Formwork System

Builder S Engineer Design Example Piled Ground Beams With Suspended Slab

Slab over the supports will pre ve n t the formation of tension cracks due to flexure when slabs are continuous for two or more spans We l d e d w i r e fabric is usually re c o m m e n d e d for tempera t u r e and shrinkage rei n f o rc e m e n t Reinforced concrete slab systems on steel decks Decking can serve as form, shoring andHeat Loss through an Insulated Slab Windows 33% Roof/Ceiling 8% Slab 15% 6 Doors 5% Walls 39% Insulation and Fenestration Criteria Table Insulation and Fenestration Requirements by Componenta CLIMATE ZONE FENESTRATION UFACTORb SKYLIGHTb UFACTOR GLAZED FENESTRATIONb,e SHGC CEILING RVALUE WOOD FRAME WALL RVALUE MASS WALL RVALUEi FLOORThickness of concrete slab depends on loads and size of the slab In general, 6 inch (150mm) slab thickness is considered for residential and commercial buildings with reinforcement details as per design Thereof, How does a suspended slab work?

Structure Magazine Creating An Opening In Existing Floors

Beam And Block Floor Suppliers Bison Precast Concrete

Posted I am trying to create garage foundation walls to support 8" preformed cement slabs for a room under the garage The manufacturer recommends a 12" foundation shelf inside the stem walls to suspend the slab and then be able to pour the 4" garage floor slab on top I am struggling finding a way to create this type ofThe present invention relates to a formwork arrangement for forming a suspended concrete floor slab comprising a change in level in an underside thereof, a support bracket for use with such a formwork arrangement, and a method for employing theSo quick and easy to install, Speedfloor is a lightweight, costeffective system that's perfect for multistoried residential or commercial buildings and parking garages Whether it's one story or fifteen, the recipe is very simple take sufficient quantity of

Floor Structure Guide Flooring Concrete Floors Interlocking Bricks

Suspended Concrete Floor Slab Formwork System

This one detail changed the functionality of both the suspended floor and the trench drains A seemingly unrelated detail, it proved to be vitally important to the project's longterm success In the case of Two Rivers Brewing, they temporarily fixed the problem with more epoxy floor coating🕑 Reading time 1 minuteConcrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab ContentsConcrete Floor Slab Construction Process1 Assemble and Erect Formwork for Slab2 Prepare and Place Reinforcement for Slab3 Pour,RIW/TD/153 Typical detail at top of internal retaining wall with suspended floor pdf RIW/TD/156 Insulated Concrete Formwork & Masonry Below Ground Retaining Wall/Slab Interface Plus Gas RIW/TD/801 Typical ground bearing slab detail GEOVENT & GROUND LEVEL VENT BOX pdf

Does Concrete Floor Slab Drawing House Plan House Plans

Garages Suspended Slabs Youtube

K 2 = (132 – d b)/100;Building on a great idea Speedfloor, the unique suspended concrete flooring system, is an innovation to the building industry! The ground floor is made up of suspended concrete slab or beam and block floor, supported by the external and internal load bearing walls, which transfer the loads to the foundations below Both precast concrete planks or slabs can be used, as well as cast in situ reinforced slabs along with beam and block systems

Concrete Composite Floors Construction Details Structural Detailer

Suspended Floors All You Need To Know Thermohouse

A Smartslab suspended concrete floor is noncombustible therefore making it ideal for those building in bush fire prone areas TOTAL SERVICE SMARTSLAB provides a total service for the design and construction of suspended slabs Each slab is individually designed and all our work is installed and certified by an experienced SMARTSLAB teamThe Speedfloor Suspended Concrete Flooring is a unique, composite floor of steel and concrete that makes light work of pouring anything from single level, to multistoried structures There is no propping required Simply assemble the joists, add structural supports and you are ready to pour Load vs Span Calculator1 = 13 for a horizontal bar with > 300mm of concrete cast below it and k 1 = 10 for all other bars;

Structure Magazine Creating An Opening In Existing Floors

Structure Suspended Slab Home Building In Vancouver

Part 1 Twoway Slabs This article is the first in a series on recommended reinforcement details for castinplace concrete construction Twoway slabs are generally defined as suspended slabs where the ratio of the long to the short side of a slab panel is 2 or less In twoway construction, load transfer is by bending in two directionsSuspended slabs are made of concrete and steel mesh, the same as a ground slabShrinkagecompensating concrete slabs on ground The de sign of suspended floors should conform to requirements of ACI 318 and ACI 4211R See Section 12 for relevant work by these and other committees This guide identifies the various classes of floors as to • use, • design details as they apply to construction,

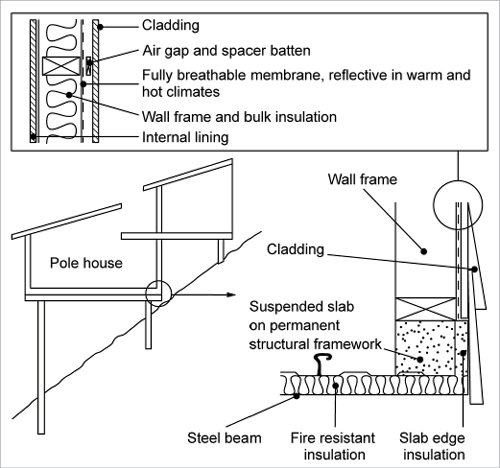

Concrete Slab Floors Yourhome

E5mcff30 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Concrete slab Suspended slab formwork and rebar in place, ready for concrete pour A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steel reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, whileFor one thing forming suspending slab take time and a lot of labor On top of that those forms have to remain in place until the concrete reach its strength before considered safe to remove which can take up to 4 weeks or moreHow thick is a suspended concrete slab?

Roof Structure Concrete Slab Structural Engineering

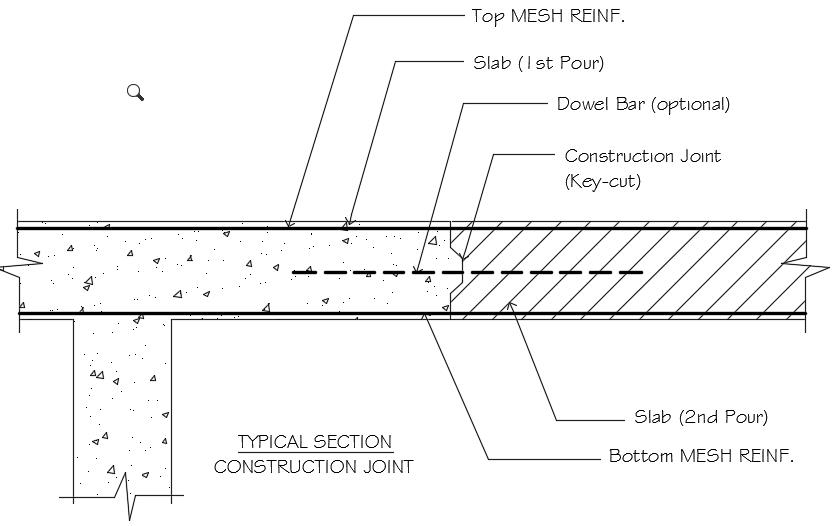

Construction Joint In Slabs The Structural World

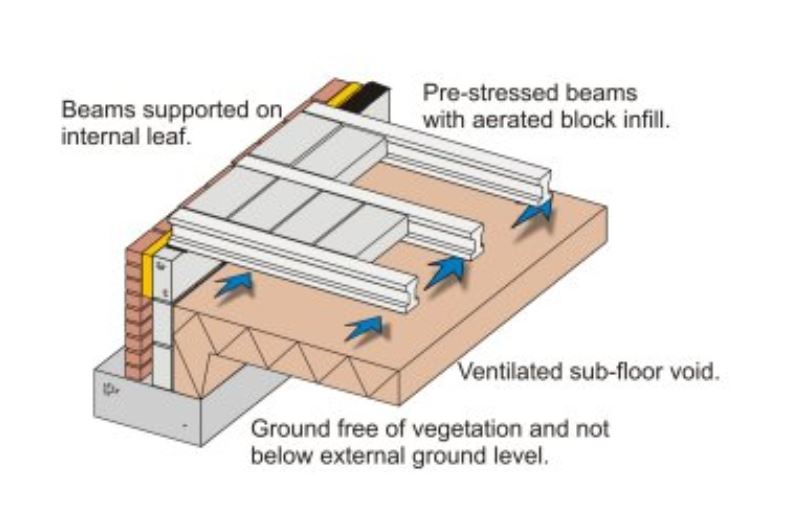

A suspended floor is a ground floor with a void underneath the structure The floor can be formed in various ways, using timber joists, precast concrete panels, block and beam system or cast insitu with reinforced concrete However, the floor structure is supported by external and internal walls Supports underneath the floor are permanent and include sleeper walls or timberThe R value for an uninsulated concrete slab is approximately 01 per 150mm A higher R value means that the material has better insulation properties 40mm Slabmate will add R1 to the concrete slab Types Of Concrete Slabs There are many types of concrete slabs including slabonground, suspended slab and precast slab Excellent for garage slabs with shop or media room below!

Suspended Garage Slab From Design Build Specialists Steel Concepts

Detail Post Floor Details First In Architecture

Openings in Concrete Floor Slabs BUILDINGS If you took an advanced concrete design course, you probably had a good introduction to the design of twoway slabsAlthough all multistory buildings require multiple small slab penetrations for routing of plumbing, fire protection piping, and ductwork between floorsSuspended floors are normally made up of 2 materials, either timber joists or a concrete beam system There are quite a lot of variations on these types of floor, mainly depending on what use you intend for that floor area and the floor finish In recent years the use of suspended concrete floors has become common place normally in the commercial sector, but to a lesser degree, even Concrete Suspended Slabs Suspended slabs are upper floors of the ground that do not come into direct contact with the Earth They are often used to build floors for the upper stories of the house, but they can also be laid on top of the prebuilt walls to form a floor

Concrete Slab Floors Yourhome

Building Guidelines Concrete Floors Slabs

K 3 = 10 ‐015(c d –d b)/d b (but 07≤k 3 ≤10) c d is the smaller of the concrete cover to the bar or half the clear distance to the next parallel bar; The cost of concrete for a slab garage floor includes the delivery of concrete and any material overages as a result of waste It doesn't include labour, supplies such as reinforcing bar or building permit fees As per the present market rates, the average cost of concrete for a 400square foot slab, the typical size for a twocar garageSlab Depth 40"140" cm Slab Depth (Formula) Span/36 Column Size 1"240" cm Drop Panel Width 1/3 Span Length (Minimum) Drop Panel Depth25 x Slab Thickness Floor to Floor Height 10'16' 3054 m

Prestressed Concrete First Floor First Floors Slab Construction Suspended Precast Concrete Floor

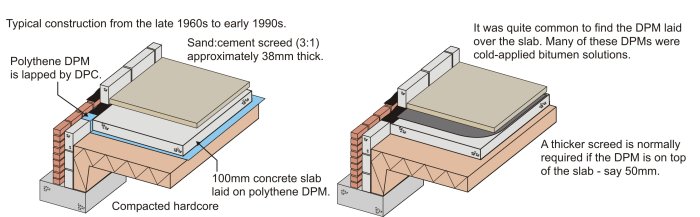

Concrete Slab Floor Construction Branz Renovate

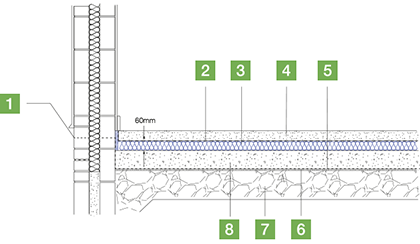

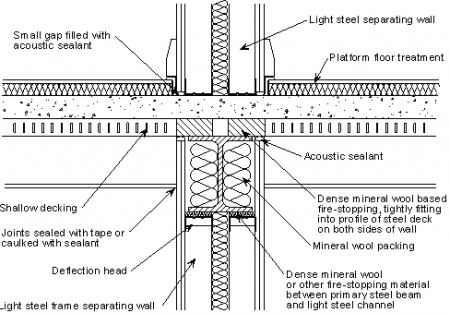

The Floor Panels and Beam Forms provide excellent insulation, which is ideal for slabs with radiant infloor heating systems Suspended concrete floors are fire safe and provide a sound barrier Provides a safe working deck for utility and rebar placement prior to concrete placementE5MCFF30 Suspended InSitu Concrete Floor, Insulation Below Slab Build Up External Masonry Cavity Wall Masonry Outer Leaf (λ = 077) 100mm Aircrete Block Inner Leaf (λ = 019 W/mK) Full Fill Insulation 150mm Cast InSitu Suspended Slab• Concrete floor beams provide a high level of thermal insulation and fire resistance • A standard or wide beam solution is well suited to open plan designs with large span requirements – An excellent alternative to concrete slab and timber floors • Maintenance Free • Easy to handle SUSPENDED BEAM AND BLOCK FLOOR WIDE BEAM 125mm 170mm

Suspended Floors All You Need To Know Thermohouse

Transportable Concrete Floor Speedfloor

Three worked examples of precast unit floors in different building types are also included Structural design guidance provided in previously published three SCI publications, Design of composite beams using precast concrete slabs (P287), Design of asymmetric Slimflor beams with precast concrete slabs (P342)and Design of multistorey bracedSuspended concrete slab is referred to a cement slab that is not in contact with the ground This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground The most common application of suspended slab in residential construction is used at garage floor where below the garage floor is a storage room

Building Guidelines Drawings Section B Concrete Construction

Concrete Slab Floors Yourhome

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

E5smew23 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Prefabricated Joist Suspended System Prestressed Concrete Floor Slab Machine Buy Concrete Slab Making Machine Prestressed Concrete Machine Prestressed Concrete Slab Making Machines Product On Alibaba Com

First Floor Concrete Slabs What You Need To Know Eco Built

1

Detail Post Floor Details First In Architecture

1

Solved Question 1 A Suspended Concrete Floor Slab For Office Chegg Com

Building Guidelines Drawings Section B Concrete Construction

Ground Floor Insulation Below Concrete Slab Polyfoam Xps

Foundations Original Details Branz Renovate

The Device Reinforced Concrete Slab Basement Floor Download Scientific Diagram

Detail Post Floor Details First In Architecture

Building Guidelines Concrete Floors Slabs

Concrete Floor Slab Construction Process The Constructor

Zlabform Suspended Slab Flooring System Architecture Design

8 Suspended Slab Ideas Steel Frame Construction Steel Deck Architecture Details

5 Types Of Concrete Slabs Construction Uses

Hollowcore Floors Concrete Products Bison Precast Flooring

Concrete Vs Timber Floors

Green Building Materials Insul Deck Icf Eps Concrete Decking System For Floors Roofs Tilt Up Walls Decks Gh Building Systems Ga

Building Guidelines Concrete Floors Slabs

Building Guidelines Concrete Floors Slabs

Kore Insulation Auf Twitter Kore Floor Is A High Performance Floor Insulation System For Use Below A Concrete Floor Slab Below A Cement Based Screed On A Concrete Slab With A Hardcore

Suspended Floors All You Need To Know Thermohouse

Building Guidelines Drawings Section B Concrete Construction

Our Suspended Ground Floor Slab Express Concrete Facebook

Concrete Slab Wikiwand

Build Diy Suspended Concrete Ground Floors

Building Guidelines Concrete Floors Slabs

5 Things To Look For When Inspecting A Suspended Concrete Slab

Building Guidelines Concrete Floors Slabs

Reference Holorib

Farm Structures Ch5 Elements Of Construction Floors Roofs

E5mcpf28 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Figure B 10 Figure B 10 Alternative Floor Slab Detail The Suspended Reinforced Concrete Garage Workshop Plans Concrete Structural Drawing

Concrete Formwork For Slabs

Lightweight Suspended Concrete

5 1 Damp Proofing Concrete Floors Nhbc Standards 21 Nhbc Standards 21

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Evolution Of Building Elements

1

Construction And Detailing 1 Ppt Video Online Download

Borders Underfloor Heating Supply Water Filled Underfloor Heating For Concrete And Suspended Timber Floors

Concrete Slab Construction Pouring A Concrete Slab Cement Floors

Fbe 03 Building Construction Science Lecture 3 Floor

6 Ground Floors Construction Studies

Concrete Slab Floors Yourhome

Quality Construction Of Suspended Floors Concrete Construction Magazine

Suspended Slabs 4site London Basements

Spray Foam Insulation Concrete Slab Floor

Evolution Of Building Elements

Eurima Suspended Concrete Floors

Articles And Advice Insulation Kingspan Great Britain

The Device Reinforced Concrete Slab Basement Floor Download Scientific Diagram

Garage Foundation Foundation Footing Suspended Concrete Slab

Suspended Slabs

Major Project Warehouse Office Ppt Video Online Download

Floor Systems Steelconstruction Info

Concrete Floor Slab Construction Process The Constructor

Sbs Suspended Beam Slab Prestressed Concrete Slab System Stock Photo Alamy

Builder S Engineer Suspended Ground Floor Slabs

Insulation For Ground Floors Designing Buildings Wiki

Concrete Slab Floors Yourhome

Suspended Concrete Slab Suspended Slab Cement Slab

Slab On Grade Foundation Design Slab On Grade Design

Farm Structures Ch5 Elements Of Construction Floors Roofs

Ground Floors Concrete And Suspended Timber Types Of

Prestressed Concrete Beam And Block Floors Design Construction Installation Suspended Floors

Detail Post Floor Details First In Architecture

Suspended Ground Floor Slab Reinforcement Avi Youtube

Suspended Floors All You Need To Know Thermohouse

Floors And Flooring Sans Building Regulations South Africa

6 4 7 Precast Concrete Nhbc Standards 21 Nhbc Standards 21

Suspended Garage Slab From Design Build Specialists Steel Concepts

Structure Suspended Slab Home Building In Vancouver

Suspended Concrete Floor Slab Formwork System

1

0 件のコメント:

コメントを投稿